There are many kinds of casting technology. how should we choose a economic, efficient casting process, which can meet our quality adequately. Qingdao Refidus share some information as following.

Sand casting

There are two sand casting methods with different cost and quality level.

Sand casting process usually cast grey iron, ductile iron, carbon steel, etc.

Green sand casting is the most cost-saving casting process, In this process, granular refractory sand is coated with a mixture of clay and water.

Resin sand casting process can cast better surface and precise dimension than green sand casting, due to the resin-bonded sand. However, this process costs more than green sand casting process.

Lear more about our sand casting capacity

Investment casting

Investment casting technology is usually used to cast material of carbon steel, stainless steel, nickel alloy, super alloy, etc.

- Water glass investment casting

Water glass process use middle temperature wax and de-wax through high temperature water. the final surface roughness and the accuracy of the castings are not enough good, comparing with other investment casting processes. however it is still much better than sand casting process. - Silica sol investment casting

We use high temperature wax and de-wax by flash fire. and ceramic mold material is silica sol and zircon sand which is more expensive than quartz sand, which is used in water glass process. So the final surface and the accuracy of the casting is much better. Silica sol investment casting is our main production line right now. - Vacuum casting casting

With the special pouring process through lower press or vacuum furnace, vacuum casting process can make optimal casting properties. So we can get complex and difficult castings by this method.

Learn more about our investment casting capacity

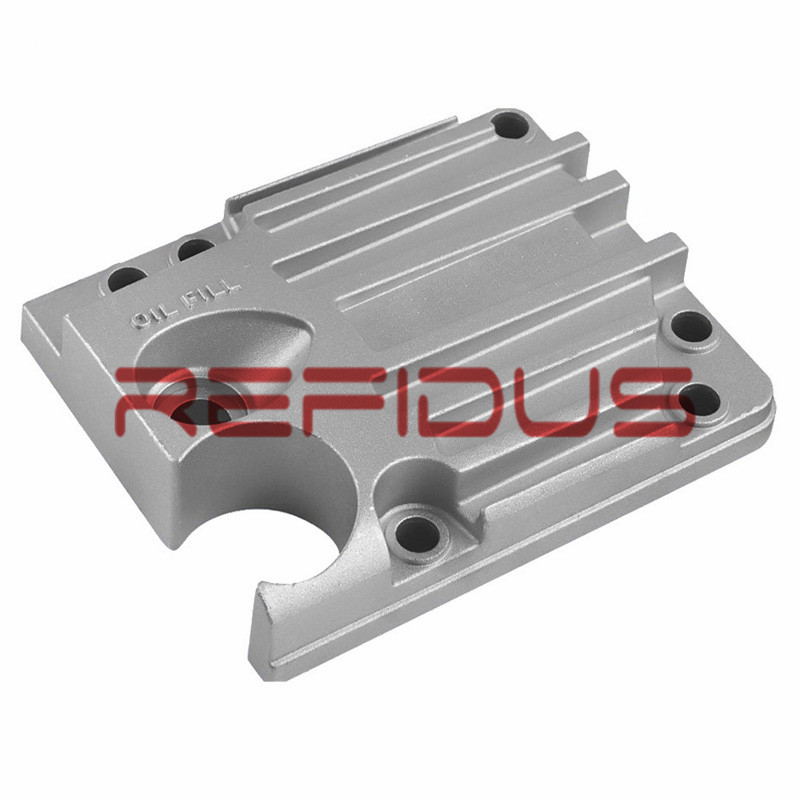

Die casting

Some aluminum alloy and zinc alloy is suitable for die casting process, such as A380. ADC12, Zamak3, Zamak5, etc.

Through high pressure casting machine, we can make die casting parts much efficient and steady easily. Characteristics of die casting process is as following,

- Thin wall and complex shape

- High producing efficiency in mass production.

- Die casting mould need more cost

Lear more about our die casting capacity