Main products

Casting

Investment casting and die casting precision up to from CT4 to CT6 level according to ISO8062

Forging

Die forging capacity from 350 tons to 800 tons, free forging capacity from 600 tons to 12000 tons

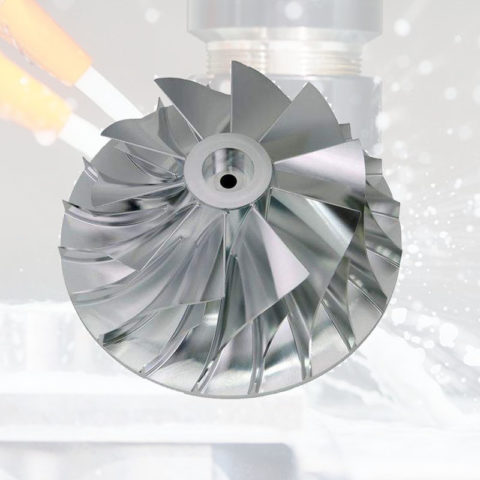

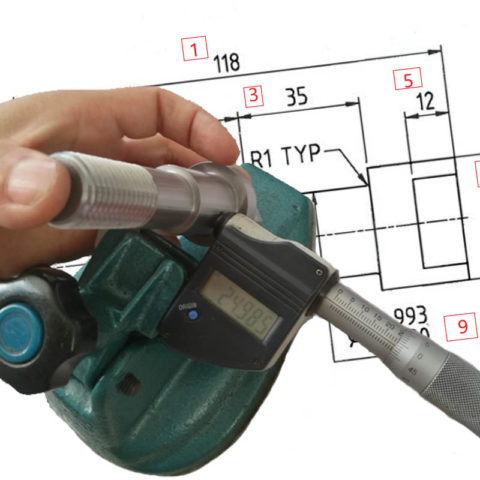

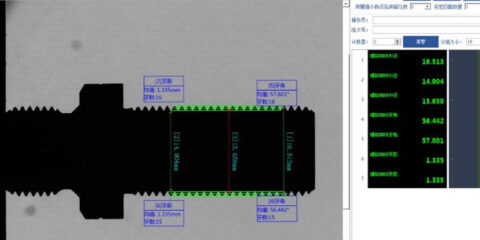

Machining

Machining precision up to 0.002mm, service: turning, milling, CNC machining, tapping, drilling, etc

CAE technology

Advanced technical method and rich industry experience help us avoiding develop risk saving production cost from the beginning to fine products

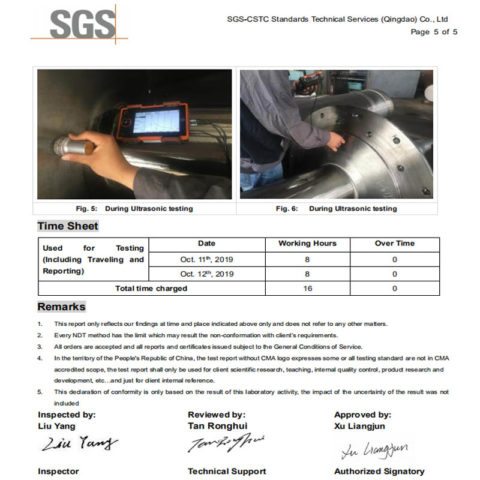

Strict and traceable inspection

Quantity control under ISO9001 system, strict and traceable quality inspection make sure only qualified fine products be delivered to customers.

Advantages

Optimal process rote for lower cost

Basing on customer's drawing and requirement, we will choose the most suitable process rote and equipment for lower cost and best quality.

Quality control through whole process

High quality awareness team with same value see our reputation as our eyes. QC and QA team guarantee quality through whole process

Our professional team will serve you from the inquiry stage to whole product life. Contact with us now, your will get a quotation within 24 hours

Main production

Custom processing parts for prototype and mass production from China, customized CNC machining part, turning, lathing, milling, grinding part according to drawings or samples, such as shaft, special thread fitting, impeller, body, cover, bracket, etc.

-

Machining precision

Liner tolerance up to 0.002mm(0.00008inch) through CNC machines from America,

We are also providing common productions through engine milling machines.

-

Casting capacity

Our investment castings can meet tolerance of CT5 per ISO8062(GB/T6414). Our production capacity is 200 tons per month.

We also have from 80 to 1600 tons die casting machines, which can produce die castings from 15 gram to kilograms.

-

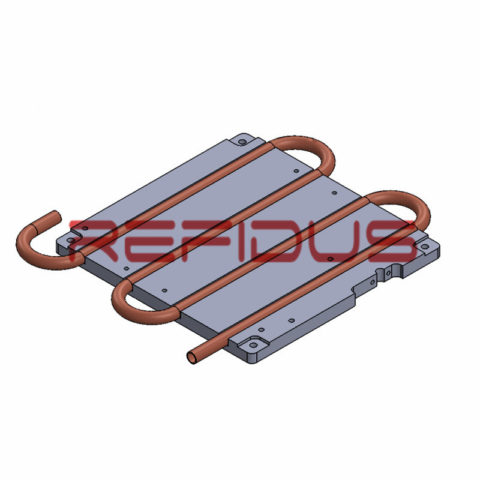

Heat sink

We are supplying heat sink, including liquid cooling plate, extrusion heat sink, die casting heat sink, skiving fin heat sink, forged heat sink, etc.

Our heat exchanger production include plate heat exchanger, shell and tube heat exchanger, etc.

-

CAD/CAE simulation

Our skilled engineer can design with you together from the beginning develop period through 2d and 3d design software,

FEA simulation is available for the material saving and developing period cutting.