As a customized OEM and ODM metal parts vendor in China, We specialize in investment castings, die castings, forgings and precise machining parts.

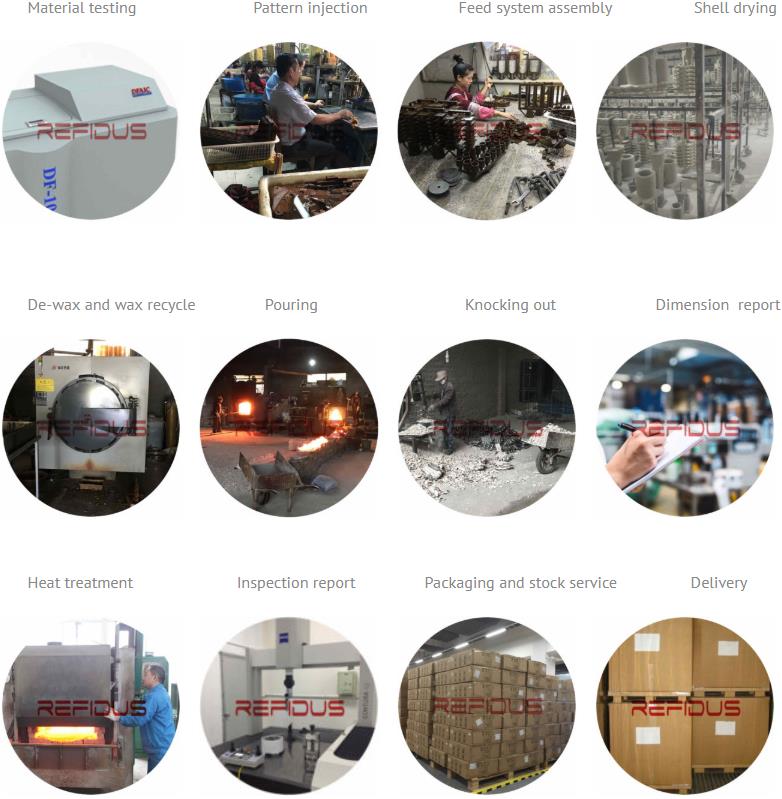

Investment casting process

Our investment casting service are including water glass investment casting, silica sol in vestment casting, vacuum investment casting.

Water glass casting process is with lower cost and high production efficiency than silica sol and vacuum. Meanwhile silica sol investment and vacuum investment casting provide more accurate dimension and complex shape.

Our water glass casting capacity is 200 tons per month, silica sol casting is 100 tons per month, vacuum investment casting is 50 tons per month.

Die casting process

We manufacture aluminum and zinc die casting parts through cold and hot chamber die casting machines with the capacities of 80, 160, 280, 600, 800, 1600 tons.

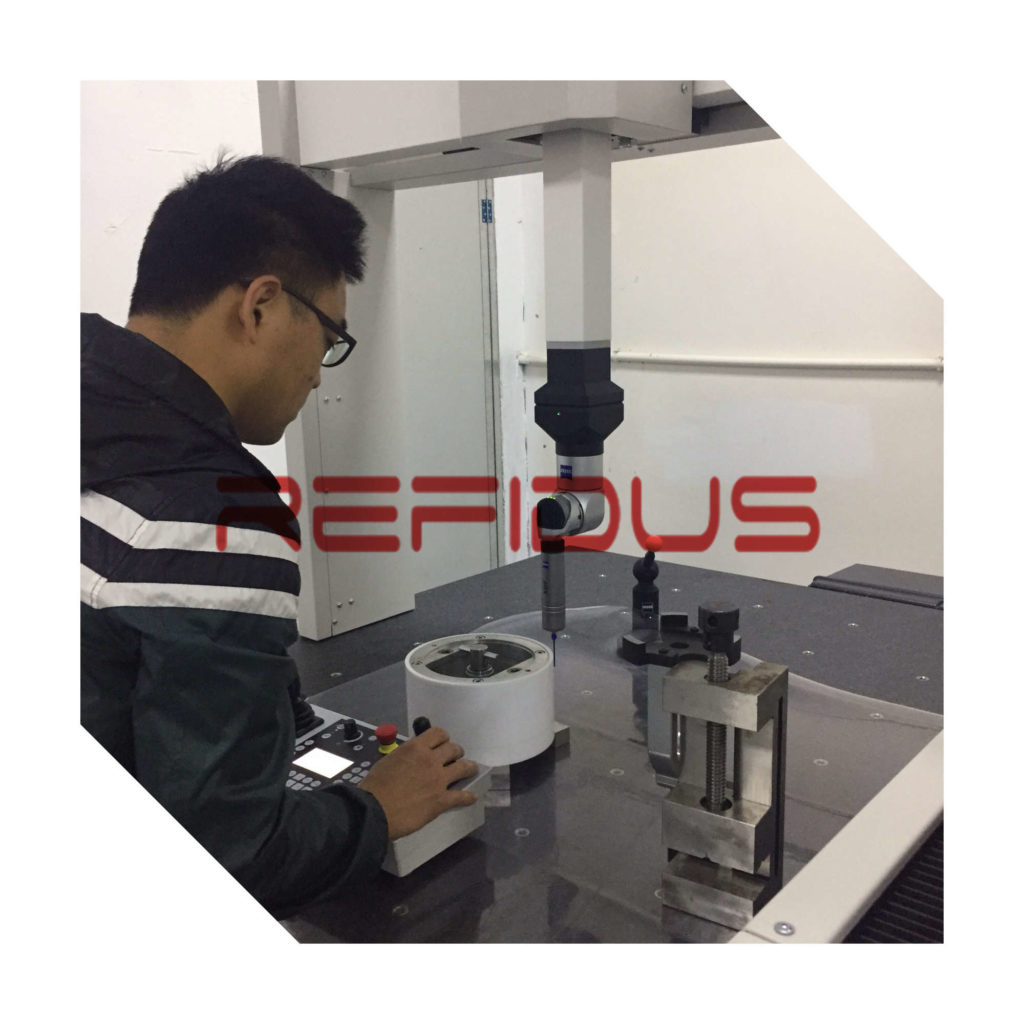

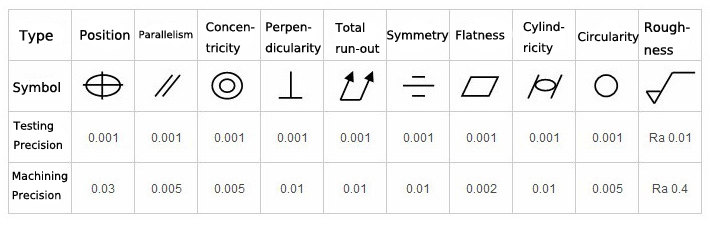

Precision machining process

We provide both 5-axis CNC machining service and common engine machining service with the most economic method according to the drawings. Our tolerance can reach up to 5 micron per requirement.

All metals and plastics processed are including kinds of common and exotic materials. Such as iron, stainless steel, 304, 316, duplex, etc; carbon steel, aluminum, copper, kovar, invar, titanium, TA1, TA2, TA3, etc; PP, PA, PU, nylon, torlon, PEEK, delrin and other special exotic alloys and polymers.

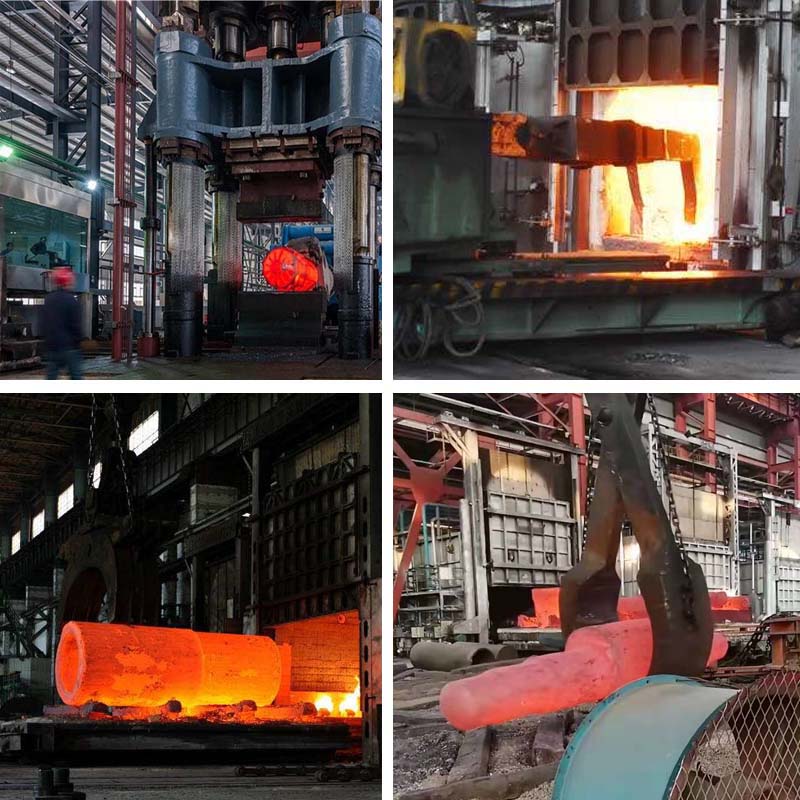

Forging process

Our pressure machine capacity is from 350 tons to 12000 tons. we provide both die forging and free forging parts

Application

Our OEM and ODM productions are wildly used in industries of power, textile, chemical, machinery, automobile, food, communication, automation. Such as structural component, function part, exterior part, heat sink, cooling plate, etc.