Casting process is operated as the most widely material molding technology in the world. Lower cost, good quality, in-time delivery make china casting industry growing rapidly these years.

Investment casting process cast parts more complex shape, precise dimension and better surface roughness than sand casting.

As a high quality china precision casting OEM manufacturer, Refidus provides three investment casting process, water glass investment casting, silica sol investment casting, vacuum investment casting.

We produce top level precision castings with customized dimensions, shapes, surface and hardness. All kinds of casting metal alloy are available.

Investment casting process

We strictly control every process to keep steady high quality and lower cost. material testing, pattern injection, feed system assembly, shell drying, de-wax and wax recycle, pouring, knocking out, dimension inspection, heat treatment, final inspection, packaging and stock, delivery.

Material testing

Pattern injection

Feed system assembly

Shell drying

De-wax

Pouring

Knocking out

Dimension report

Heat treatment

Inspection report

Packaging and stock

Delivery

Investment casting process comparing

- Water glass investment casting process

Water glass process use middle temperature wax and de-wax through high temperature water. The most important difference to silica sol is that ceramic shell material is water glass and quartz sand which is cheaper. So the final surface roughness and the accuracy of the castings will not be enough good, however it is still much better than sand casting process. - Silica sol investment casting process

We use high temperature wax and de-wax by flash fire. and ceramic mold material is silica sol and zircon sand which is more expensive than quartz sand. The final surface and the accuracy of the casting will be much better. Silica sol investment casting is our main production line right now. - Vacuum casting casting process

Melt nickel alloy, high temperature alloy, precious alloy be poured under lower press or vacuum furnace, which makes vacuum casting technology different to normal investment technology. Vacuum casting process can make optimal casting properties. As a result, we can achieve complex and difficult castings successfully.

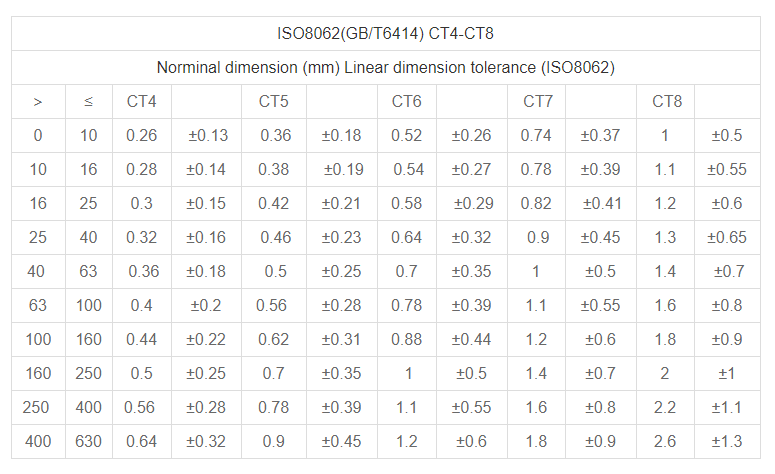

Precision casting tolerance

Our investment casting parts can meet CT5-CT6 tolerance level according to ISO8062.

Engineer team will advise you the suitable casting process according to your requirement and usage. Basing on our rich experience and using modern CAE, FEA method, We can reduce the material waste rate on feed system and avoid casting defect, such as shrinkage defects, gas porosity, pouring metal defects, metallurgical defects,etc.

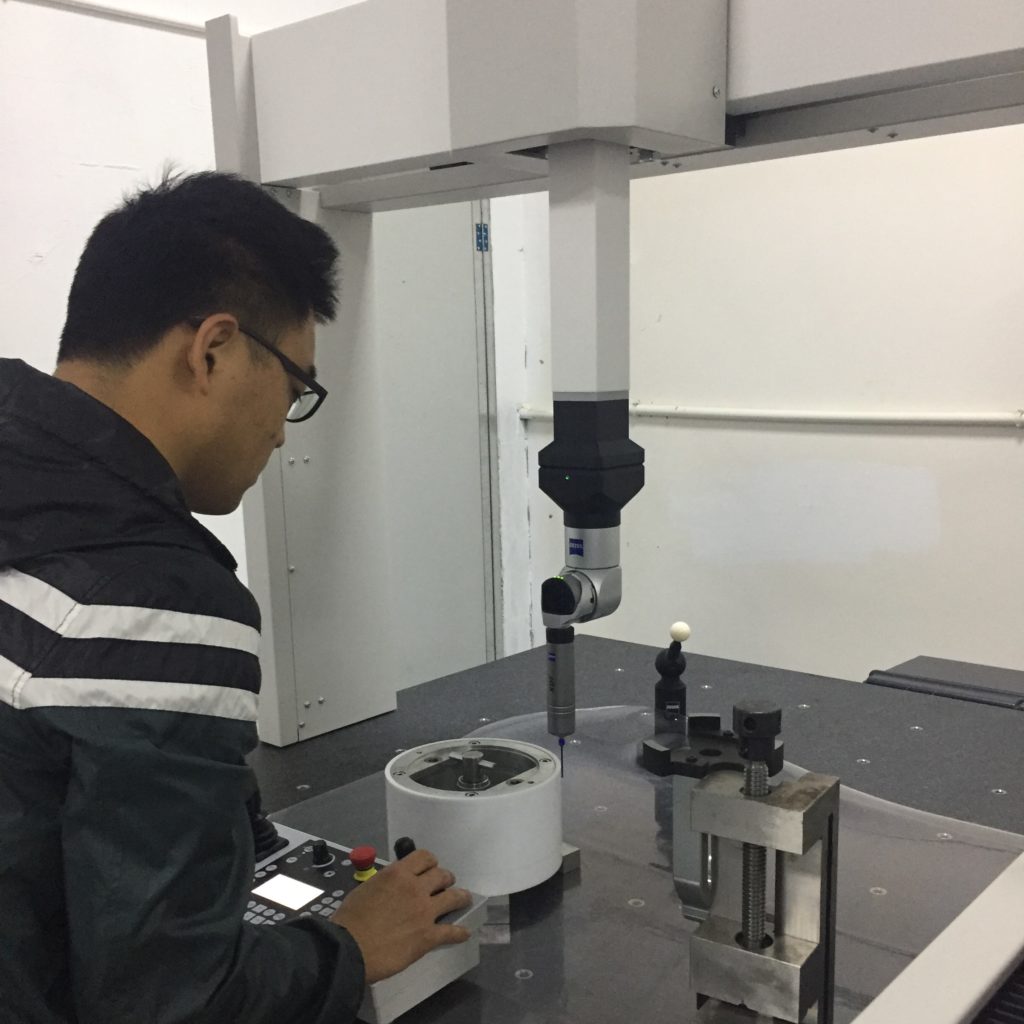

Quality inspection

Through strictly quality control system, every batch investment castings quality can be guaranteed by Qingdao Refidus.

To ensure the best quality and on-time delivery in China, we control the quality in each process. Both manufacturing stage and before shipping, we will send you testing reports and production photos.

Spectrograph

Dye penetration inspection

Surfagauge

Tension tester

Vernier caliper

Screw gauge

Coating thickness testing

Coordinate measuring

Contact with us, let us be your reliable partner in China.