We are providing contract manufacturing stamping and welding parts according to customers’ drawings, under the strict requirement of material, dimension, surface, mechanical property, etc.

Through forty high efficient stamping machines with the capacity from 15 to 400 tons, gas protective welding machines, tapping machines, etc. we are producing precision stamping parts from prototype stage to mass production stage.

Custom surface coating and value-added deep machining process at Refidus are also workable and outstanding.

For instance, painting, powder coating, enamel coating, electroplating, hot dip galvanizing, etc.

Stamping service

| Material: | Customized, Such as steel, stainless steel, carbon steel, pre-galvanized steel, aluminum, etc. |

| Process: | Laser cutting, punching, stamping, deep drawing, milling, drilling, tapping, welding, surface treatment. |

| Surface treatment: | E-Coating , Zinc-Plated , Hot-dip galvanized, Chrome-Plated, Powder Coating as per customers request. |

| Tolerance: | According to individual production. |

| Capacity: | Laser cutting machine, Press machine, Punching machine, Milling machine, Drilling machine, CNC machining. |

| Drawing formats: | DWG, STP, IGS, PDF, etc. |

| MOQ: | Different parts with different MOQ. |

| Delivery time: | About 30 days for 20-100 tons in mass production. |

| Inspection: | Inspection reports and photos will be sent to you before shipping. |

Stamping workshop

Stamping tooling in stock

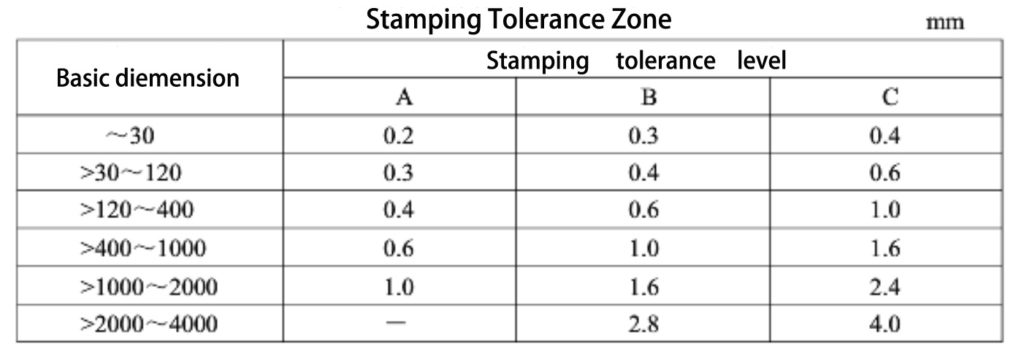

Stamping tolerance

Stamping parts are generally manufactured per C level according to GB/T13914-2002, and they are also can be deep machined to meet higher precision requirement.

Our characteristics, quick quotation, continuous quality, timely delivery. Feel free to contact with us, start our cooperation.