We are skilled with metal machining part with our rich experience and excellent equipment.

According to your drawings and designs, we will choose right material and suitable process to get the accurate shape with lower cost to save your cost and time.

What we provide for machining service

| Material: | Stainless steel 201/303/304/400/316,etc; Steel Q235,20#,45#,1020,1045,etc; Aluminum LD5/LD7/66061/6063/7075/5052, etc; Brass C36000(C26800), C37700(HPb59),C38500(HPb58),C2200(CuZn37), C28000(CuZn40) etc. |

| Process: | Raw material cutting, Turning, CNC lathe machining, CNC milling, CNC grinding; CNC boring; Drilling, Surface treatment |

| Surface treatment: | Hardness anodizing black/clear, oxidizing, electro-polishing, Plating |

| Tolerance: | +/-0.001mm or +/- 0.00004" |

| MOQ: | Depends on different productions, we provide prototype machining service. |

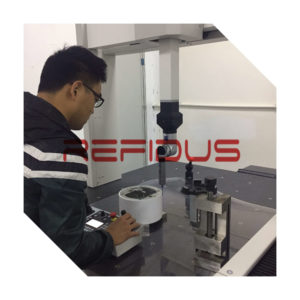

| Testing equipment | Vernier caliper, Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester. |

| Packaging: | Seaworthy packing with protection for productions or customers' requirement |

| Delivery: | Express, sea transportation or by air according to your requirement for different order. |

Our machining equipment

- Hardinge CNC machine 1550*650mm, Hass CNC machine 1550*650mm, Fuyu CNC machine 1020*500mm; whose precision is 0.005~0.01mm(0.0002inch~0.0004inch)

- Jiande precision grinding machine 1550*650mm, whose precision is 0.005mm(0.0002inch); Hanchang precision grinding machine, whose precision is 0.002mm(0.00008inch)

- Sodick wire cutting machine, whose precision is 0.002mm(0.0008inch)

- Other CNC milling machine, CNC lathe machine, Engine lathe, Driling, Tapping, cutting machine.