An array of different process of cold plates enable Refidus to swiftly meet specific fluid compatibility and performance requirements. For example, we offer friction stir welded (FSW) aluminum cooling plate, press-lock tubed cooling plate, vacuum brazing cooling plate, etc.

Liquid cooling plate is widely used in fields of medical equipment, laser cutting machine, IGBT, electronics equipment, military application, aerospace. We provide ODM service and OEM production with strict quality standard.

| Production: | Liquid cooling plate. |

| Material: | Aluminum6061/6063, Copper, Copper-nickle alloy. Stainless steel. |

| Process: | Extrusion, CNC, Milling, Drilling, Soldering, Surface treatment. |

| Surface: | Passivation, Plating, Oxidizing. |

| OEM/ODM: | Both OEM/ODM and CAE service are available. |

| Dimension: | Depends on different process,up to 1000mm*1000mm. |

| Package: | Seaworthy packing with protection for productions or customers' requirement. |

| MOQ: | Depends on individual production, Usually 10 pcs. |

| Lead time: | Depends on individual production to be discussed and production plan. |

| Application: | Heat sink, Military usage, Medical equipment, Laser cutting machine, IGBT, Electronics equipment. |

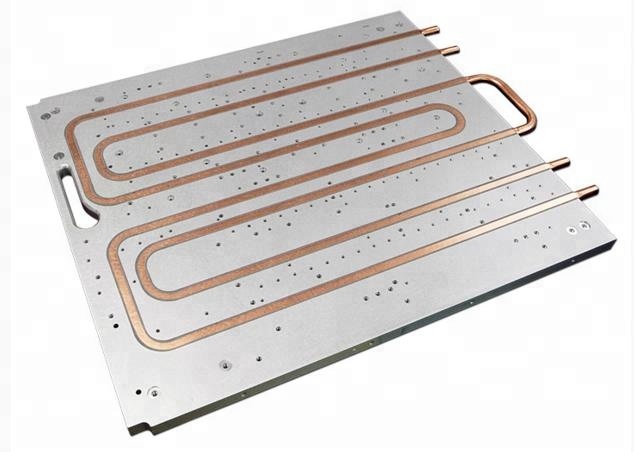

Tubed cooling plate

Tubed water/liquid cooling plate consist of aluminum base plate and bended tubes.

Material:

- Base plate, aluminum, copper;

- Tube, copper, stainless steel, copper-nickel alloy.

Advantage:

- Tooling cost is lower, usually only tube bending tool is necessary.

- Liquid system can be with high internal pressure.

- Both two plate can be used to transfer heat from two heat source through mill each surface.

- Easy to be designed to meet mounting dimension of heat source.

Vacuum brazing cooling plate

Vacuum brazing water cooling plate is made by vacuum brazing of two aluminum plates milled with same liquid channel.

Material: Aluminum

Advantage: Lower pressure drop; more heat transfer area; Cost saving during mass production.

Friction stir welding (FSW) cooling plate

FSW liquid cooling plate is welded by two aluminum plate through mechanical press and friction heat.

Advantage: high reliability without leak risk due to common welding defects.

Disadvantage: High cost and high requirement to operators.

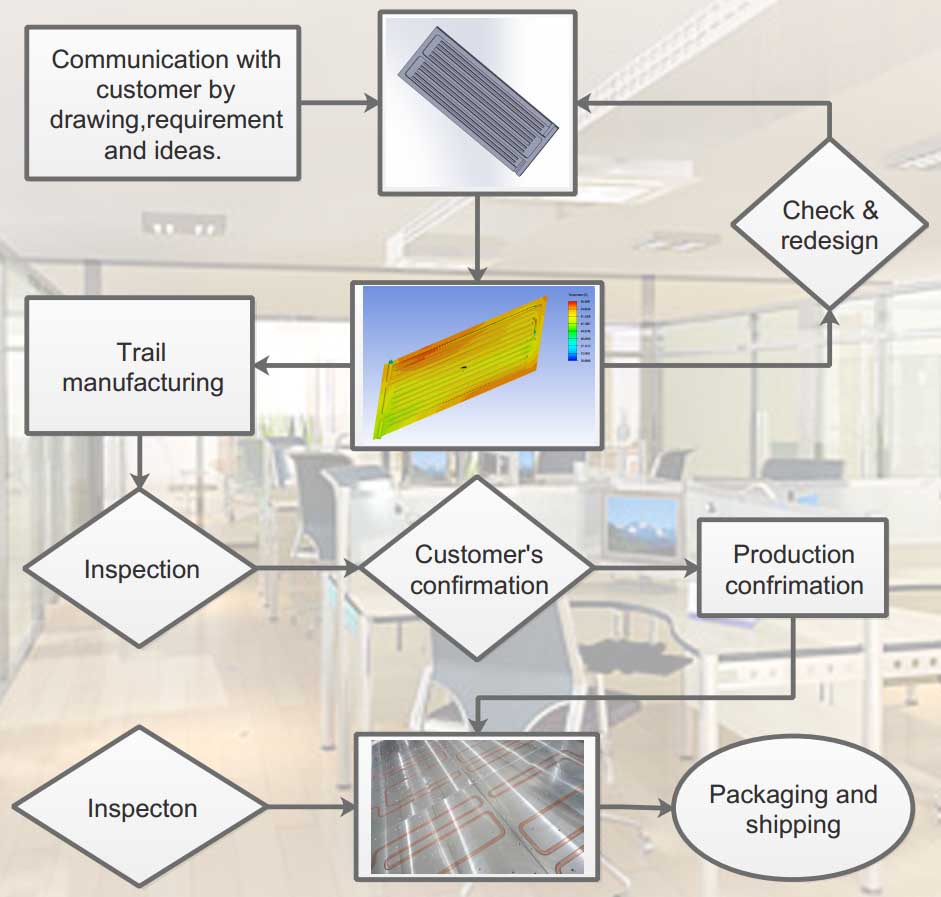

ODM process

OEM equipment