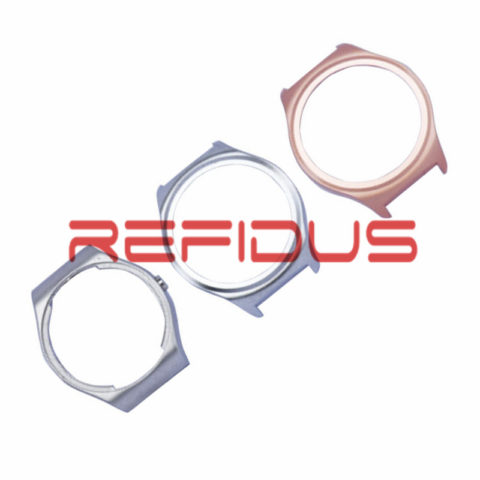

Electrophoresis surface die casting components from China

Colorful surface OEM die casting parts

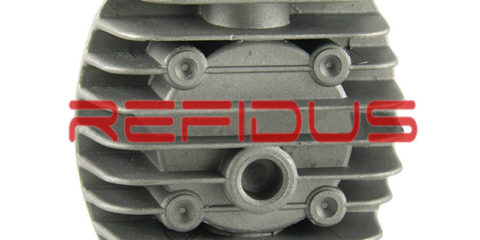

Die casting aluminum and zinc alloy parts are generally used in various applications. for instance, intelligent lock panel, vape shells, electronics covers, lighter bodys, heat sinks, nameplates, decoration accessories, etc.

Both cold chamber and hot chamber die casting can be contract manufactured for aluminum and zinc alloy at Refidus.

Through the die casting machines of 80, 160, 280, 600, 800, 1600 tons , we provide customers continuous quality with a competitive cost.

Value-added customized surface treatment and deep machining service are both welcomed.

We provide various surface treatment, such as plating, power coating, painting, oxidization, electrophoresis, etc.

Due to our efficiency machining equipment and experienced workers, we are also producing final productions with excellent quality.

Contract manufacturing for die casting service

| Material: | aluminum alloy A380,A360.ADC12. Zinc alloy. Zamak 3#, Zamak 5#, Zamak 7#,etc. |

| Process: | Die casting, CNC machining, Milling, Tapping, Drilling, Surface treatment. |

| ODM/OEM: | Available, CAD/CAE service. |

| Surface: | Sand blasting, Plating, Power coating, Painting, Anodization, Electrophoresis, Black oxidation. |

| Packaging: | Seaworthy packing with protection for productions or customers’ requirement. |

| Delivery: | Express, sea transportation or by air according to your requirement for different order. |

| MOQ: | Depends on different productions, we provide prototype machining service. |

| Application: | Various uses, including automotive parts, heat sink,, medical parts, electronic equipment, marine parts, lighting parts, pump body, furniture parts, etc. |

Die casting and deep machining machine