Custom CNC machining unmanned aerial vehicle UAV part component

Item: Custom CNC machining unmanned aerial vehicle UAV part component

We are manufacturing OEM CNC lathing, turning, milling and machining parts of a variety of custom structures which are used kinds of application.

Component structure: Body, cover, plug, flange, joint, housing, bracket, clamp, connector, shaft, rod, wheel, blade, insert, bearing, cam, crank, block, impeller, plate, board, ring, bushing, pulley, gear, sprocket, screw, guider, sleeve, thread, fitting, leg, spindle, roller, chuck, blot, propeller, cap, hole, etc.

Application: Aviation, agriculture, medical industry, transportation industry, UAV, food processing machine, military equipment, Aerospace part, pharmaceutical equip, oil and mining machinery, automobile, timber manufacturing machine, transmission industry, energy equipment, fire fitting equipment, pipeline system, fluid equipment, etc.

Material we are machining: Carbon steel, stainless steel, alloy, super alloy, high temperature alloy, aluminum, copper, brass, bronze, titanium, hastelloy, inconel, plastic, etc and other exotic material.

Special engineering custom-made steel CNC machine part according to drawing.

Both single and mass production are available.

We are supplying rapid CNC machining part both rapid prototype and mass production.

We will choose right material and arrange suitable process to save both cost and time according to your drawings, samples or designs,

CNC machining service:

| Material: |

|

| Process: | Raw material cutting, Turning, CNC lathe machining, CNC milling, CNC grinding; CNC boring; Drilling, Surface treatment |

| Surface treatment: | Hardness anodizing black/clear, oxidizing, electro-polishing, Plating |

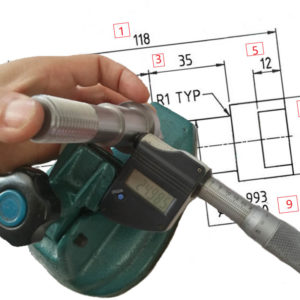

| Tolerance: | +/-0.001mm or +/- 0.00004″ |

| MOQ: | Depends on different productions, we provide prototype machining service. |

| Testing equipment | Vernier caliper, Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester. |

| Packaging: | Seaworthy packing with protection for productions or customers’ requirement |

| Delivery: | Express, sea transportation or by air according to your requirement for different order. |

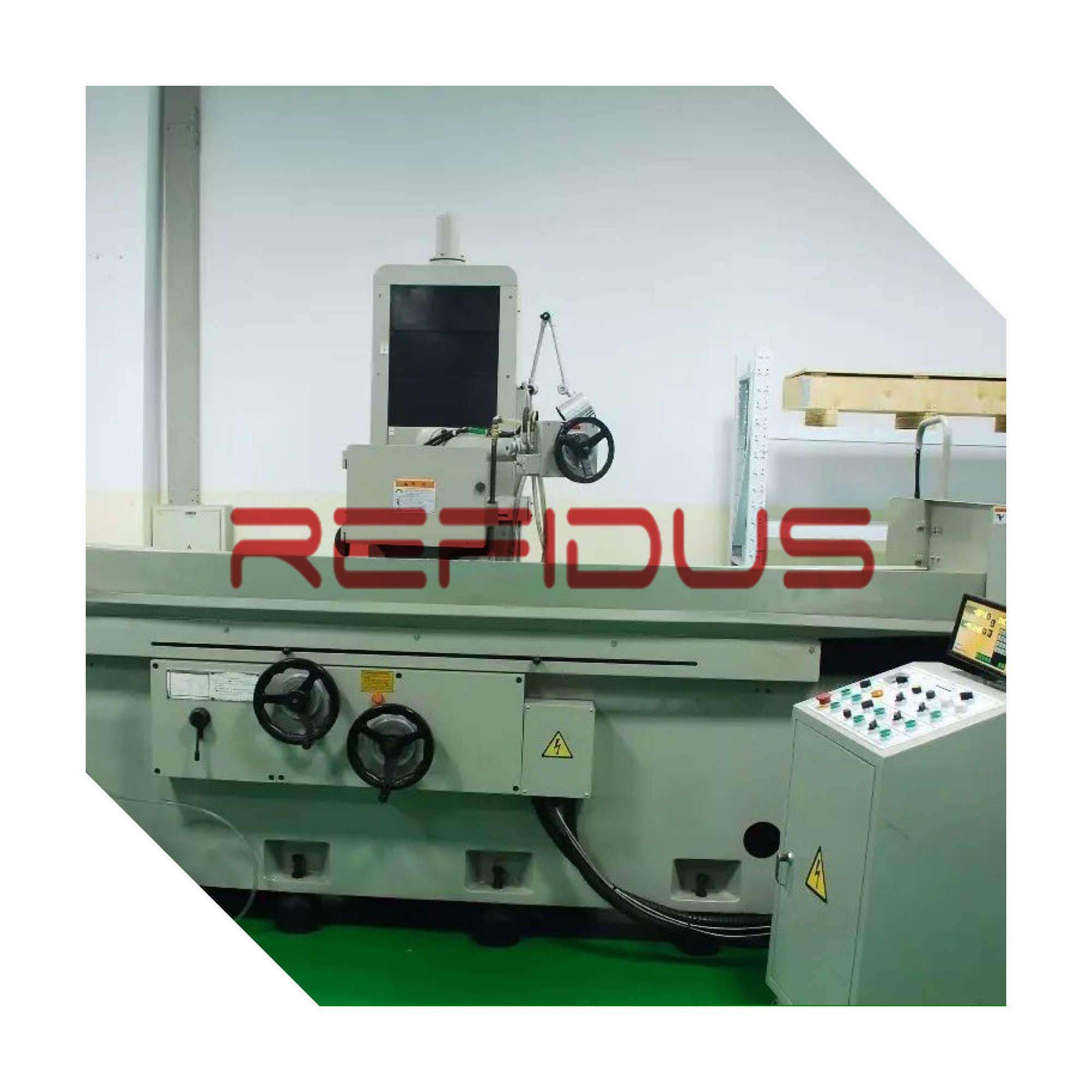

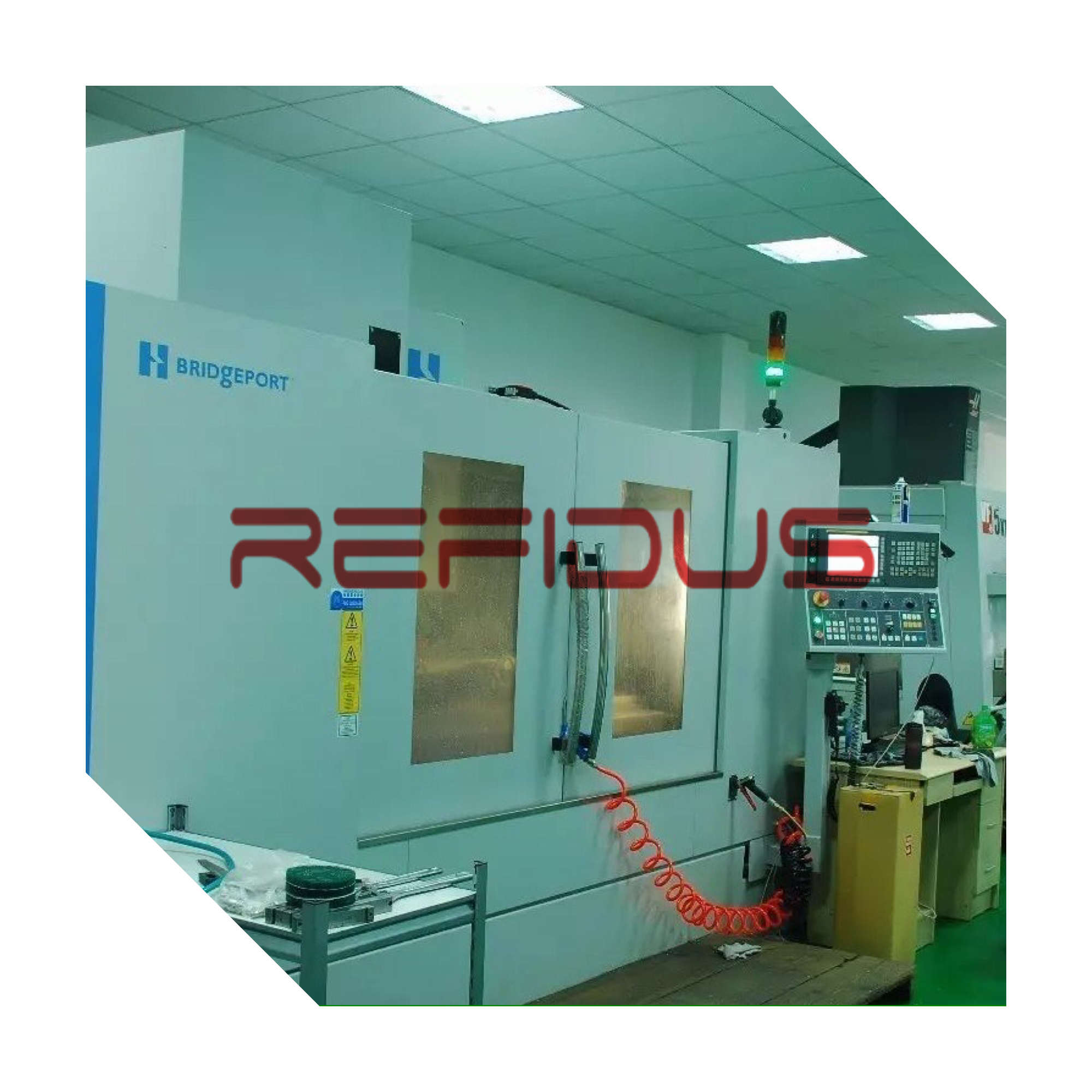

Workshop:

Product:

- Shaft tool cutter

- Titanium alloy part

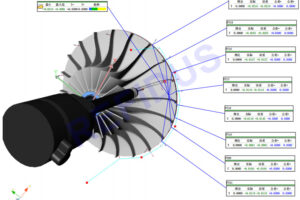

- Turbine compressor impeller

- Guide vane

- Medical machine part

- Stainless steel part

- Connecting part

- Worm gear shaft

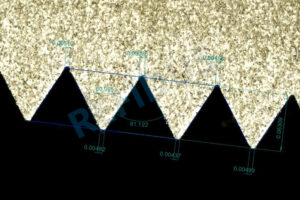

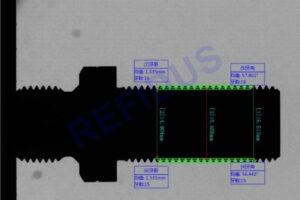

Quality inspection:

Comprehensive inspection methods include CMM and 2D projector ensure every technical requirement checked traceably and in detail.

- 2D measuring

- 2D measuring

- CMM

- 2D projector

- Surface measuring

- Mechanical test

- CMM

- Micrometer

- Thread gauge