Silica sol and water glass both are investment casting technology. But they are quite different.

Qingdao Refidus, one of dedicated investment casting manufacturers in china, is sharing some characteristic of them as following.

Different adhesive.

As the name suggests, adhesive of silica sol investment casting is silica sol. meanwhile adhesive of water glass investment casting is water glass

Different shell drying process.

Silica sol shell is drying naturally under a constant temperature and humidity environment. So it spend more time and cost. Water glass shell is drying through chemical hardener, which cost is lower.

Different wax.

Silica sol wax is used at middle temperature, water glass wax is used at low temperature.

Suit for different casting material.

Usually carbon steel apply to water glass investment casting, however silica sol investment casting process can manufacture carbon steel, stainless steel, high temperature alloy, titanium alloy, etc.

In a word, silica sol investment casting process is expensive. but it cast better quality parts, which has more accurate dimension and smooth surface.

As a professional investment casting vendor in China, Qingdao Refidus provides quality ODM and OEM investment casting components.

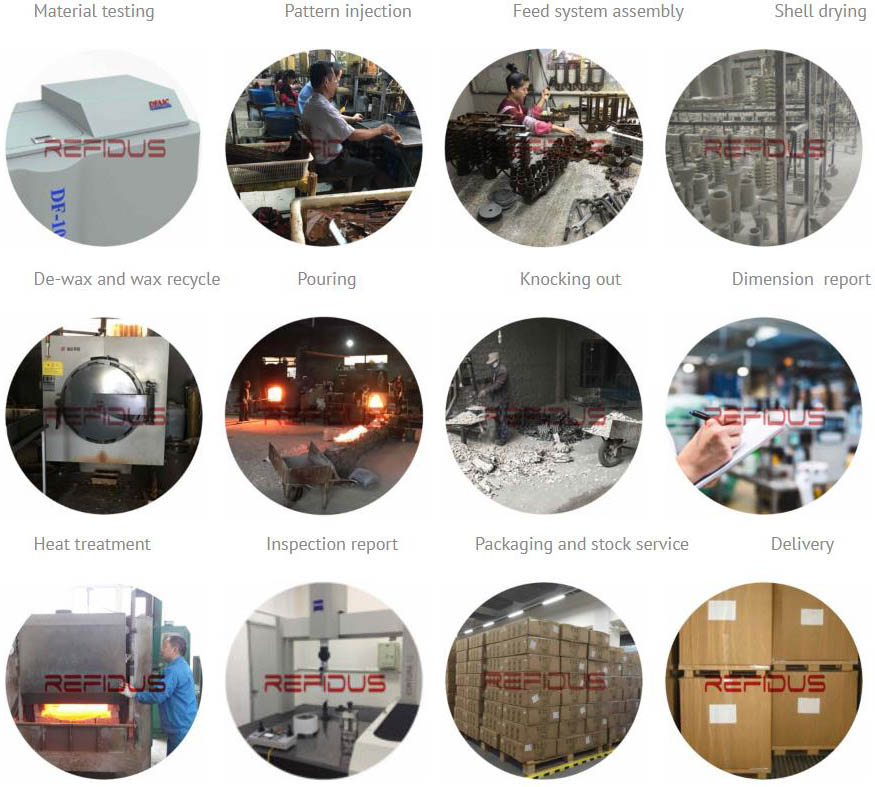

Investment casting process