Generally speaking, the dimension accuracy of precision castings is affected by the casting structure, material, molding, shell making process, roasting and pouring.

Casting structure.

Relationship of casting wall thickness and shrinking percentage. Usually, the wall more thicker, the shrinking percentage more higher, the harder to control dimension accuracy.

Material.

Carbon content in material affect dimension quality. If carbon content more higher, the shrinking percentage is higher. and the dimension and shape is more harder to be control.

Molding process.

Wax injection temperature affect the dimension and shape accuracy through affecting shrinking percentage of wax.

During the drying process, there is 10% shrinking in the first 12 hours.

The wax injection pressure and holdup time also affect dimension accuracy.

Shell making process.

The material of shell, zircon sand and zircon powder, also affects casting accuracy more or less.

Roasting.

During roasting process, we should take much care to the expansion coefficient of different shells.

The experience of investment casting manufacturers is very importance to control well accuracy of castings and developing time of new castings.

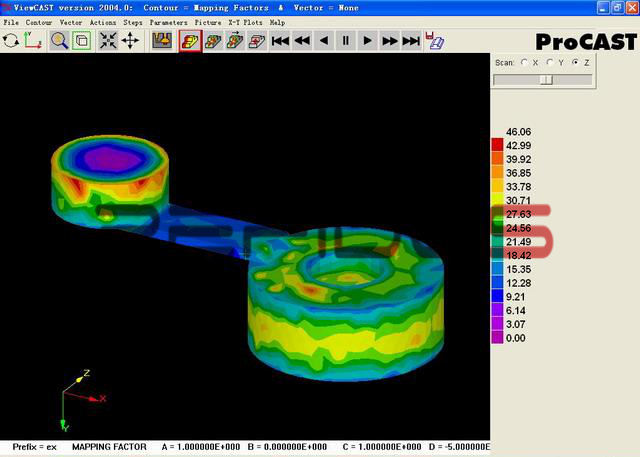

At some companies, they are pre-checking to the castings hard to control though CAE simulation, and can also avoid some mistakes.

If any doubt in castings, just contact Qingdao Refidus. As one of china best investment casting OEM companies in china, we are more than pleased to help you at any time.