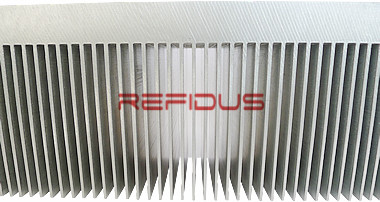

High dense fin heat sink require more higher manufacturing technology than common ones, Engineers of Qingdao Refidus Machinery Co.,Ltd. share some issues as following, which should be paid more attention to.

First of all, enough capacity of press machinery is necessary. Press extruder at Refidus are up to 6800 tons, which can ensure the good quality and smooth producing.

- For the tail extruding of high dense fin heat sink, the dimension of first aluminum alloy or pure aluminum testing bar should be 150-200 mm.

- Before the trail extruding process, the extrusion center of the aluminum extruder must be adjusted well–extrusion shaft center, ingot barrel center and outlet of the extrusion mould must be on the some horizontal line.

- The temperature of aluminum alloy rod should be between 480-520 centigrade degree during the trail manufacturing and mass production process.

- The preheated temperature of extrusion mould should be controlled at about 480 centigrade degree. The holding time of extrusion mould less than 200 mm should be more than 3 hours. However the ones more than 200 mm should keep more than 6 hours, so as the core temperature can be ensured the same with external temperature. High dense fin extruding mould should keep enough long preheated holding time, especially the wide ones.

- Before trail manufacturing or production, it is necessary to keep ingot barrel clean and equipment testing run well with out material.

- During tail manufacturing and the beginning of production, Start extruder with the minimum pressure and keep the pressure increasing slowly. During the filling process, Control the pressure from 80 to 120 Kg/cm2 generally. In normal production period, the extrusion speed is based on the pressure no more than 120 Kg/cm2.

- In the process of straightening, we should carefully check the profile changes before and after, through the moderate stress to guarantee the quality of products.

- Cutting the extrusion heat sink profile to individual dimension according to requirements. The sawing feed speed should be steady and slow. Removing the flying edges and burrs.

- Aging treatment as requirement.