CAE for investment casting process can help the designer and manufacturer reducing developing time and producing testing period.

Qingdao Refidus, professional investment casting supplier in China, share a basic guidance sample of CAE simulation of investment casting here.

Basic parameter

Material:

Mould material, Steel H13.

Casting material, A365 aluminum

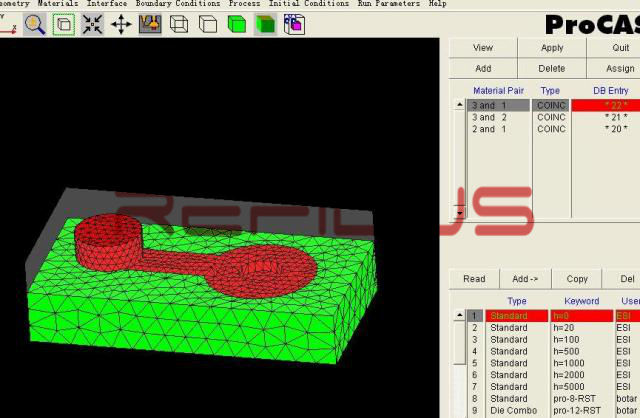

Boundary heat transfer coefficient:

Moulds, 1500

casting VS mould, 1200

Air, 8

Dressing, 80

Temperature:

Moulds, 25 degree centigrade

Casting, 700 degree centigrade

Dressing, 25 degree centigrade

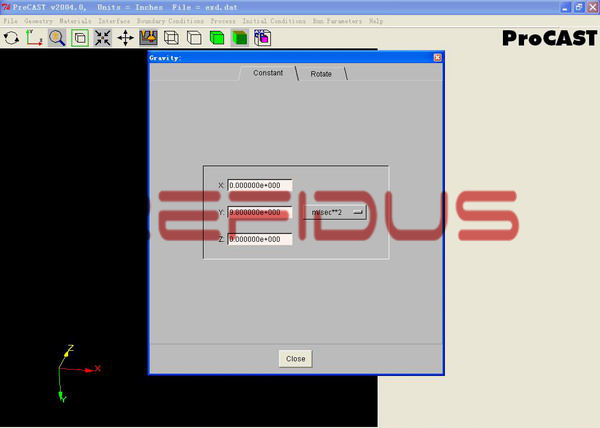

Boundary parameter:

Inter pressure, 10 bar

Inter speed, 25 meter per second

Gravitational acceleration, 9.8

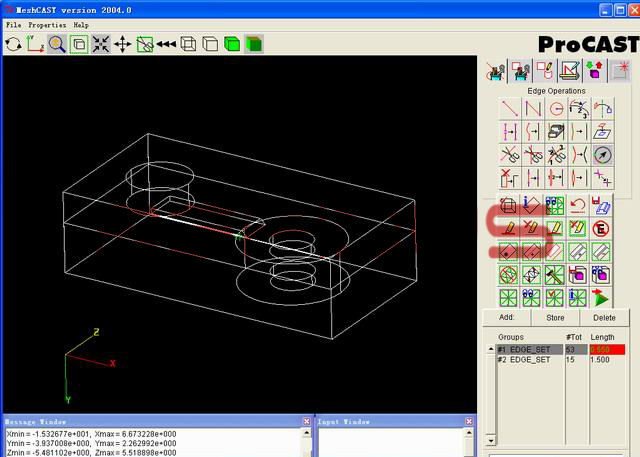

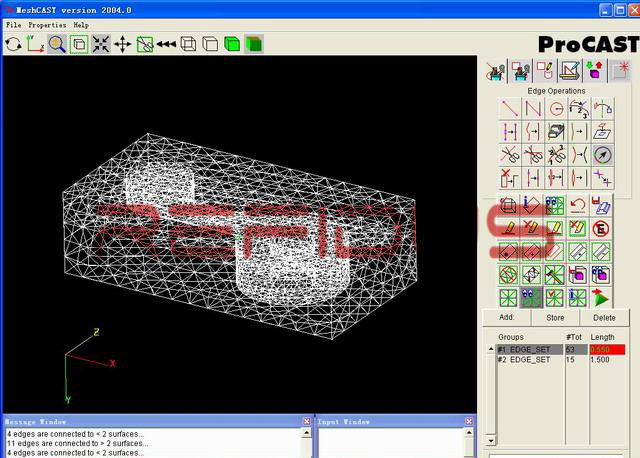

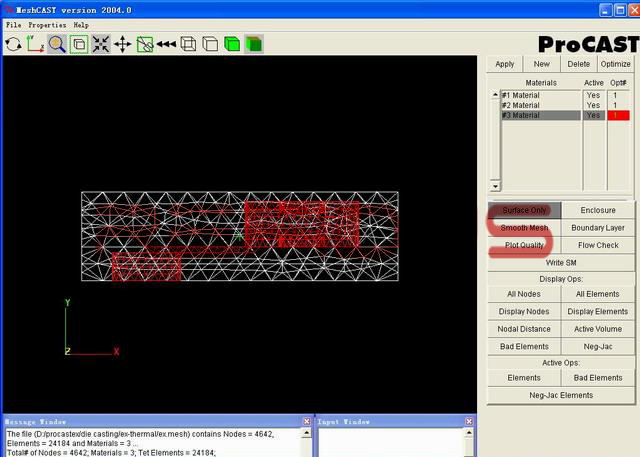

First built 3D model in CAD softwares, Meshing in mesh cast.

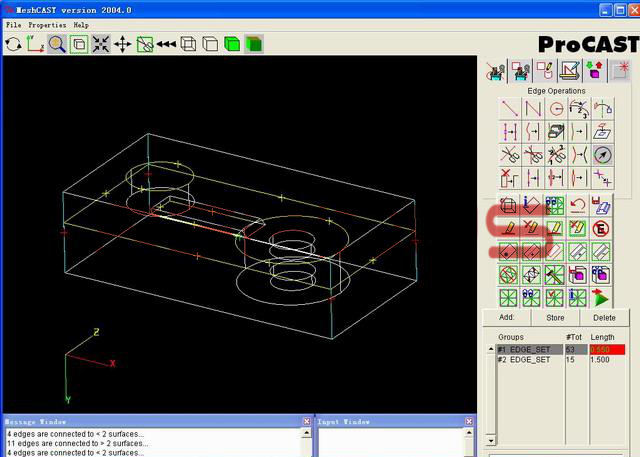

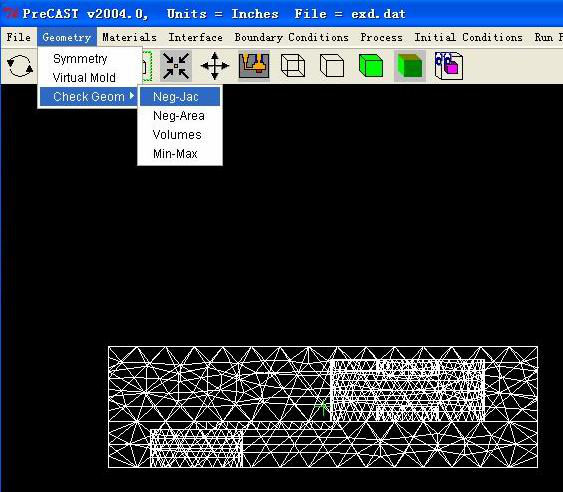

Mesh checking and modifying

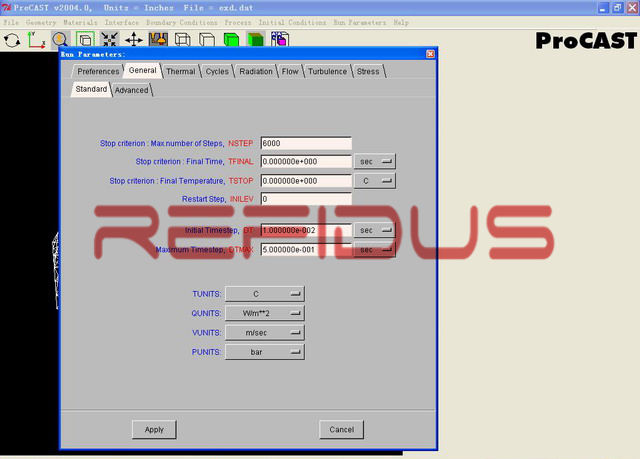

Boundary setting and parameter setting

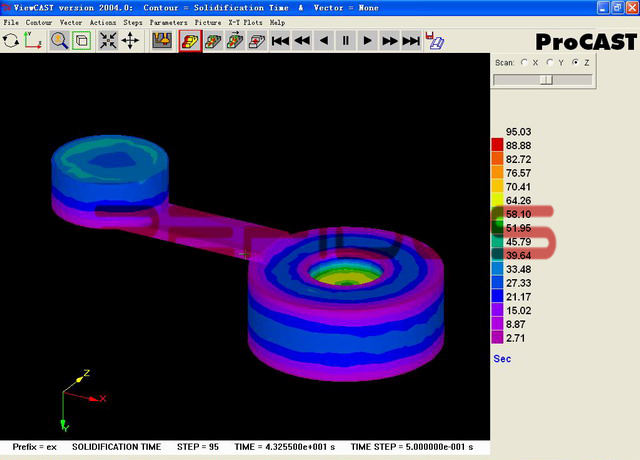

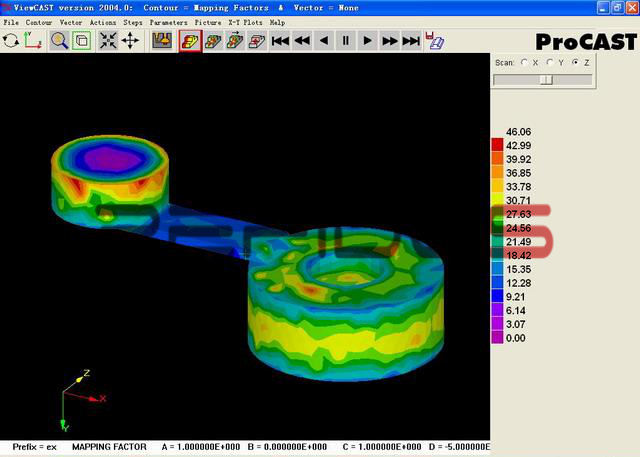

Run simulation

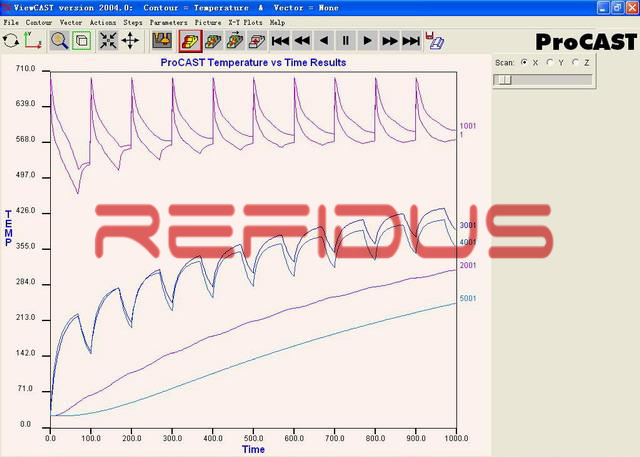

Get the result of simulation