Profile heat sink is very low cast during mass production process, due to the high efficiency production capacity in extruding process. So what should we pay attention about the design and assembly for profile heat sinks.

First, we should make sure the correct material.

As for the heat conductivity, copper is 3.85 w/cm·℃, aluminum is 2.12

w/cm·℃ , steel is 0.46 w/cm·℃. And the material cost is from higher to lower.

The contact area between heat sink and heat source should be as much as possible. Much contact area can offer lower thermal resistance.

Choose lower thermal resistance to connect heat sink and heat source. such as thin mica or polyester film.

Make sure the screw’s torsion is the same when fastening heatsink and heat source.

After assembly of heatsink, we should not machine the heat sink or source any more to avoid of thermal resistance due to stress.

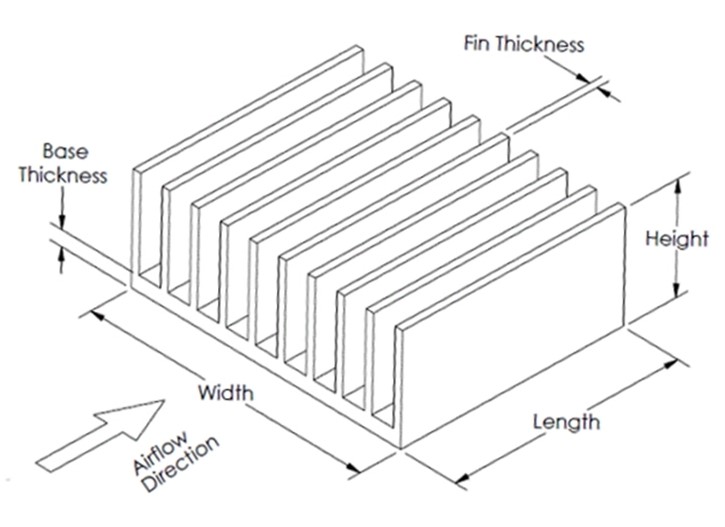

When cooling naturally, the section of heat sink should be parallel to the horizontal plane; when forced air cooling, the flow direction of airflow should be parallel to the section of heat sink profile.

Qingdao Refidus, as one of the best thermal solution and heat sink oem companies in China, serve global customers with OEM and ODM heat sink productions.

We are more thank glad to cooperate with you with heat sink productions.