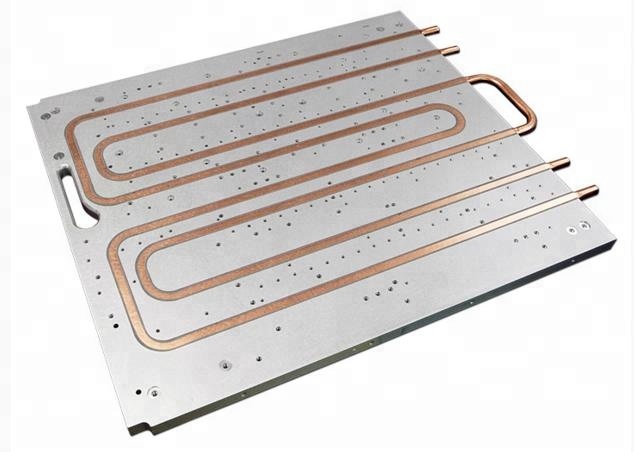

Skiving fin heat sink with thermal tube or pressed tube

Material, aluminum alloy, cooper alloy; Process, skiving, tube pressed, milling.

Consist of skiving fin heat sink and tubed cooling plate. It has all advantages from them.

Advantage of skiving fin heat sink

- There is usually no additional tool cost necessary.

- Compared with bonded fin heat sink, skiving process can get the fin and base plate as a whole part, without binder. So skiving fin heat sink is with higher thermal conductivity and more heat exchange area.

- Due to the uniform material of fin and base plate, skiving heat sink surface is easy to be treated by oxidation, passivation, etc.

- Fin height dimension up to 350mm. heat sink length up to 1000mm.

Tubed cooling plate

Tubed water/liquid cooling plate consist of aluminum base plate and bended tubes.

Material:

- Base plate, aluminum, copper;

- Tube, copper, stainless steel, copper-nickel alloy.

Advantage:

- Tooling cost is lower, usually only tube bending tool is necessary.

- Liquid system can be with high internal pressure.

- Both two plate can be used to transfer heat from two heat source through mill each surface.

- Easy to be designed to meet mounting dimension of heat source.