Machined precision casting check valve body

Material, carbon steel; Process, casting, tapping, milling.

Casting process is operated as the most widely material molding technology in the world. We can produce top level precision casting parts in customized dimensions, shapes, surface and hardness. All casting metal alloys are available.

To ensure the best quality and on-time delivery, we control the quality and progress in each process. Both manufacturing stage and before shipping, we will send you original testing reports and production photos.

Below is the basic steps of investment casting process in our foundry:

Investment casting

Material testing Pattern injection Feed system assembly Shell drying

De-wax and wax recycle Pouring Knocking out Dimension report

Heat treatment Inspection report Packaging and stock service Delivery

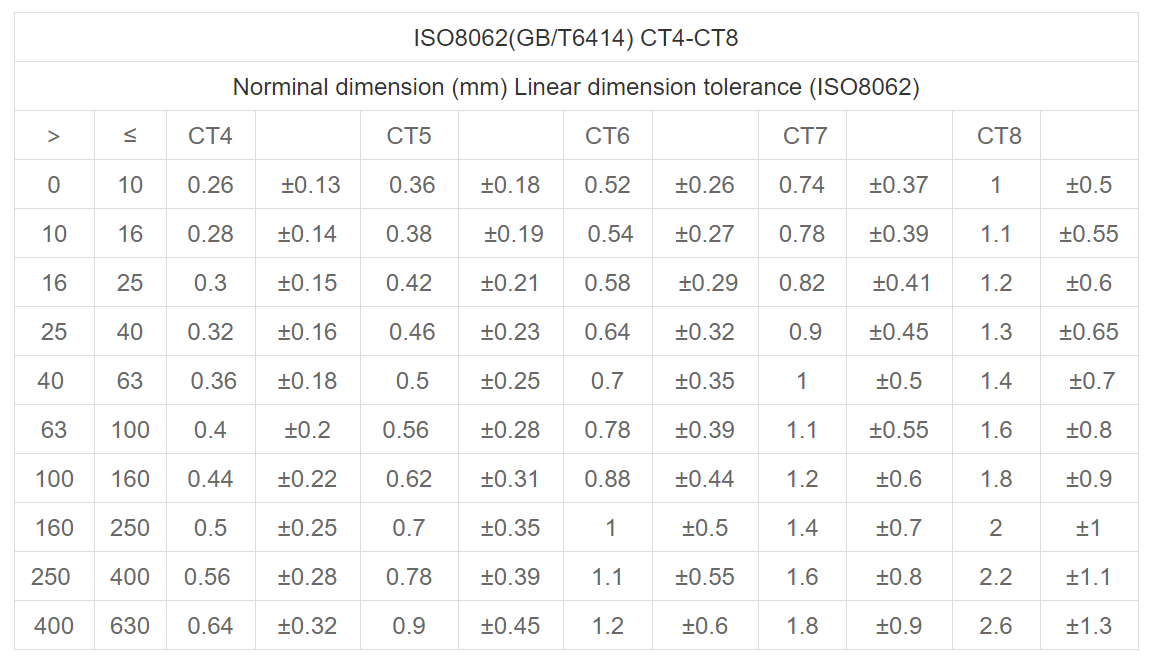

Precision casting tolerance

Water glass casting can control general linear tolerances between CT7-CT8, and lost foam casting can meet CT8-CT9, As for silica sol casting, it is CT5-CT6.

Our engineer team will discuss with you or advise you the suitable casting process according to your requirement and usage. Basing on our rich experience and using modern CAE, FEA method, We can reduce the material waste rate on feed system and avoid casting defect, such as shrinkage defects, gas porosity, pouring metal defects, metallurgical defects,etc

Value added service, Heat treatment, Surface treatment

To meet individual requirement, sometime more follow-up process is needed after casting to get accurate dimension, special hardness and some surface requirement.

Our machining equipment

- Hardinge CNC machine 1550*650mm, Hass CNC machine 1550*650mm, Fuyu CNC machine 1020*500mm; whose precision is 0.005~0.01mm(0.0002inch~0.0004inch)

- Jiande precision grinding machine 1550*650mm, whose precision is 0.005mm(0.0002inch); Hanchang precision grinding machine, whose precision is 0.002mm(0.00008inch)

- Sodick wire cutting machine, whose precision is 0.002mm(0.0008inch)

- Other CNC milling machine, CNC lathe machine, Engine lathe, Drilling, Tapping, cutting machine.

Hardness treatment, We can meet special hardness requirement though accurate heat treatment or stress treatment. such as annealing, normalizing, stress relieving, aging, tempering, etc.

Surface treatment. Our cooperated plant can provide different surface treatment, such as plating(chrome, nickel, zinc), hot dip galvanizing, spray coating, oxidizing, color-harden, carburization, etc.